Outbreaks of Bruchidius mackenziei (unofficially called the soybean bruchid) have been reported recently in soybean crops in the South Burnett and North Queensland. The bruchids were detected at harvest and postharvest, their timing matching previous reports of this pest from the Darling Downs and Burnett in 2009/10.

Bruchidius mackenziei is a native bruchid that is most likely not a true stored product pest. Adults lay eggs on the pods of maturing soybean crops and larvae and pupae are often still in seeds postharvest. Adults emerging from infested seed give the impression that this species is a stored product pest, however overseas studies show Bruchidius sp. adults do not re-infest stored grain and B. mackenziei eggs have not been found to date in stored soybean seed in Australia. The emergence of adults as late as 2-3 months postharvest may be due to slowed larval development in harvested seed with low moisture content that has been held in aeration cooled silos.

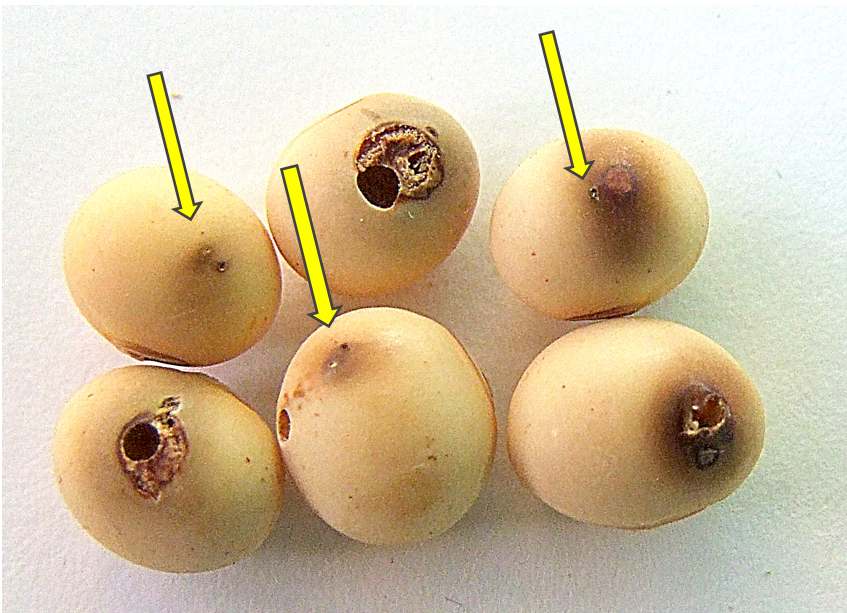

Circular exit holes made by soybean bruchid adults emerging from pupae inside infested seeds, and smaller entry holes (arrowed) made by larvae entering pods after hatching from eggs laid on the pod wall. Photo by Hugh Brier.

Identification

Soybean bruchid adults are 2.5 mm long and are grey/brown with speckled markings and sometimes paler patches on the elytra (wing covers). The antennae of the males are strongly pectinate (comb-like). The adults are readily distinguished by their colour patterns and antennal shape from other ‘bruchids’ infesting stored soybeans, notably the bean bruchid (Acanthoscelides obtectus), the cowpea bruchid (Callosobruchus maculatus), and the coffee bean weevil (Callosobruchus maculatus). Unlike soybean bruchids, these species will all continue to breed in stored soybean seed.

- Bean bruchid (Acanthoscelides obtectus) (3.5 mm) (in navy beans). This species is similar looking but is much larger than the soybean bruchid. Photo by Pat Collins.

- Cowpea bruchid (Callosobruchus maculatus) (3 mm) in mungbeans. Photo by Justin Bartlett.

- Coffee bean weevil (Araecerus fasciculatus) (3.5 mm). Photo by Joe Wessels.

Damage

Late-maturing crops are at greatest risk. Damage is similar to that caused by other bruchids and emergence windows may be seen in still-infested seeds. To date, soybean bruchid eggs have not been seen on infested seeds. However, the mere presence of bruchids is off-putting for customers who fear re-infestation in their storages. For this reason it is recommended that any bruchids found in soybeans being harvested, or in seed postharvest, are correctly identified and treated.

Note that seeds from which adults have not yet emerged often have much smaller entry holes (see earlier damage picture) made by larvae boring though the pod wall after hatching from eggs laid on the pod surface. Damage may also be confused with that caused by the caterpillar podborer, etiella (Etiella behrii), which usually results in more ragged seed damage, rather than neat circular holes.

Soybean seed being attacked by etiella (Etiella behrii) larva (10 mm long). Note the more ragged seed damage. Photo by Hugh Brier.

Monitoring and management

Given the high populations observed at harvest, this species may be detectable (as bruchid eggs on the pod walls and as adults) in the field prior to harvest. However, action at this stage is problematic as the withholding periods for many insecticides are longer than the time from detection to harvest, let alone crop dehydration after which pesticide degradation ceases. As well, insecticides won’t kill larvae already inside pods/seeds (and there are none registered for this purpose anyway).

Sieve soybeans being harvested

Use a standard grain storage insect inspection sieve (2 mm mesh) during harvest time and while unloading trucks into storage. This enables early detection of this pest and gauges the level of infestation. When bruchids are detected during harvest, aim to place infested soybeans into “sealable silos’ fitted with standard aeration cooling fans.

Aeration and fumigation timing

If bruchids are found, undertake standard aeration cooling practices if the grain is to be held in farm storages for more than 4 weeks. Aeration will create uniform grain moisture conditions in storage and lower soybean seed temperature, holding seed quality and reducing insect pest activity.

In 2 to 3 weeks’ time, once harvest is completed and the stored soybeans have been aerated for a few weeks, conduct a standard 10 day phosphine fumigation in a gas-tight, sealable storage to control the bruchids. Once fumigation and silo venting is completed, return the soybeans to aeration cooling management.

However, if the infested soybeans are to be sold off-farm within a few weeks of harvest, run aeration fans while filling silos. When the sealable silo is full, conduct a standard 10 day fumigation plus venting (1 day using aeration fan) prior to sale. Follow label directions.

Monitoring and storage hygiene

As with all stored grain, conduct regular monthly storage inspections by sieving grain samples and checking insect probe traps placed in grain at the top of the silo. Remember to also check any bags of planting seed stored in sheds.

Visual and sniffing inspections, to detect off-quality bad-smelling grain in the top of a silo, along with checking grain temperatures using a probe, are also valuable practices. Keep up-to-date storage records.

A high standard of hygiene for storages and grain handling equipment always pays dividends by reducing the risk of infestation from other storage pest species and minimises grain contamination from other grains.

For further information on grain storage pest control and management, please see information resources at www.storedgrain.com.au , or www.grdc.com.au. Storage extension specialists can be contacted on 1800 WEEVIL.

Article by Hugh Brier, Philip Burrill, and Greg Daglish.

To assist researchers to develop more effective bruchid control measures in pulse crops, we would be grateful for your reports on all infestations, Please contact DAF’s Postharvest grains research group or an AgriScience Queensland agronomist / entomologist nearest to you.

DAF entomologist and stored grain specialist contact details

- Hugh Brier 0428 188 069 Email [email protected]

- Philip Burrill 0427 696 500 Email [email protected]

- Trevor Volp 07 4529 4180 Email [email protected]

- Greg Daglish 073708 8538 Email [email protected]